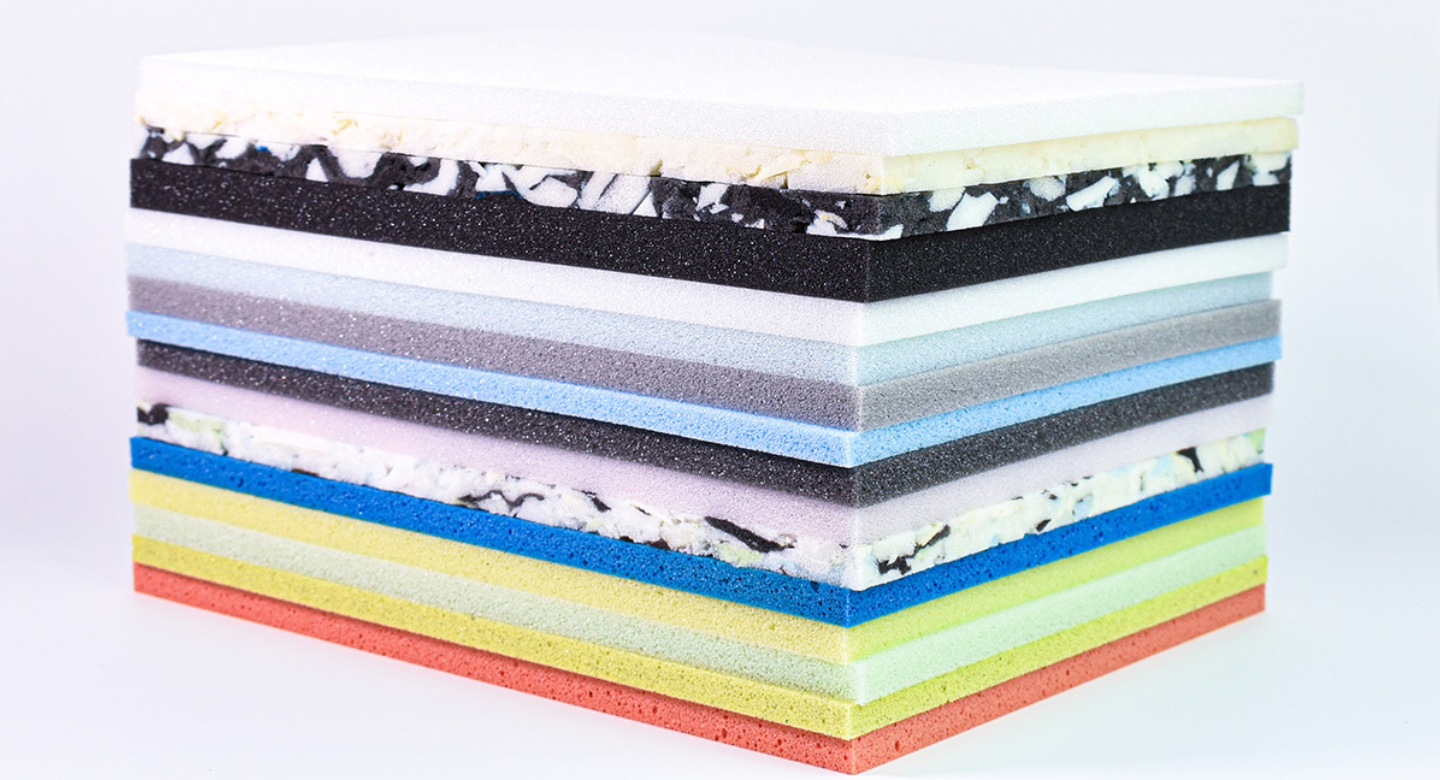

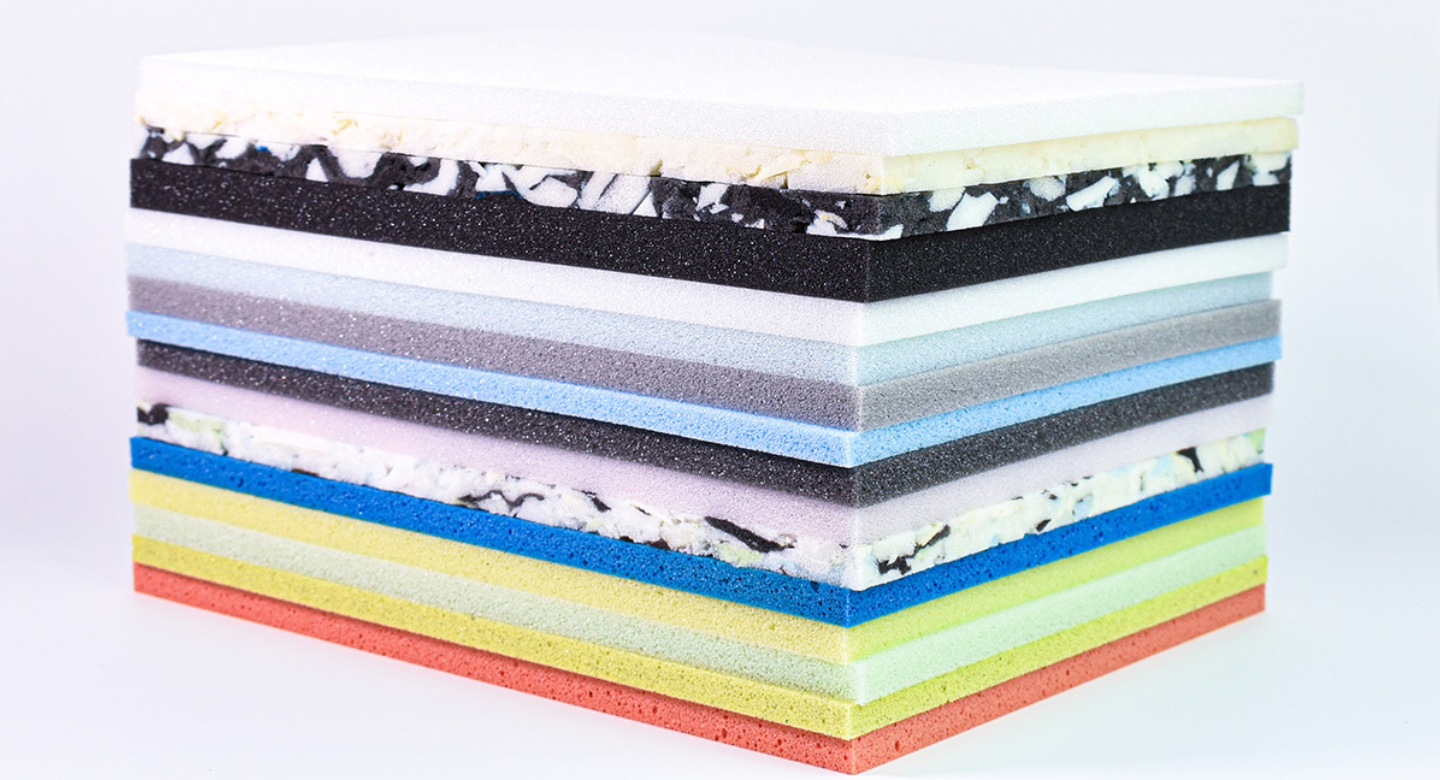

Flexible polyurethane foam (PU) is a versatile polymer created through the reaction of polyols and isocyanates. This foam is distinguished by its unique cellular structure, providing a combination of compression and resilience, resulting in excellent cushioning properties. Due to these characteristics, PU foam is the material of choice in numerous industries. It is widely used in the furniture and textile industry to offer comfort and support, in automotive seating to improve ergonomics, and in packaging for impact absorption. We offer different product lines to meet our clients’ needs: peeler rolls, sheets or blocks, memory foam, and bonded foam.

The roll or peeler foam is ideal for lamination or bonding processes, where the foam is combined with other materials like fabric for specific applications. The main advantage of our rolls is that they are produced without any seams throughout the entire material, resulting in minimal waste.

FilterFoam sheets are produced from block manufacturing and cut to the customer’s desired thickness, ranging from 3mm to 950mm depending on density. They come in a standard width and length of 2 meters x 1.2 meters, which may vary depending on the specific product.

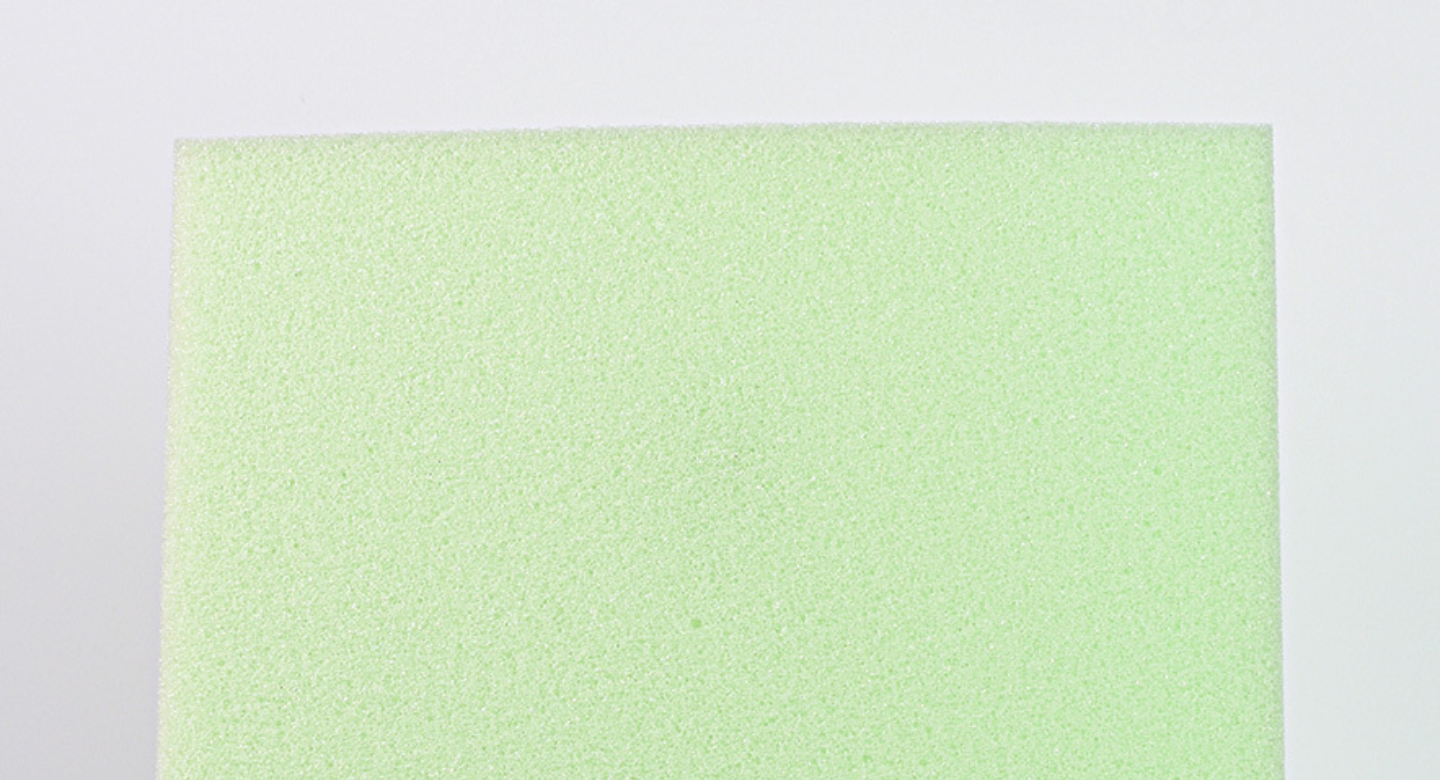

FilterMemory flex foam blocks or sheets (memory foam) ideal for footwear, mattresses, pillows, and more.

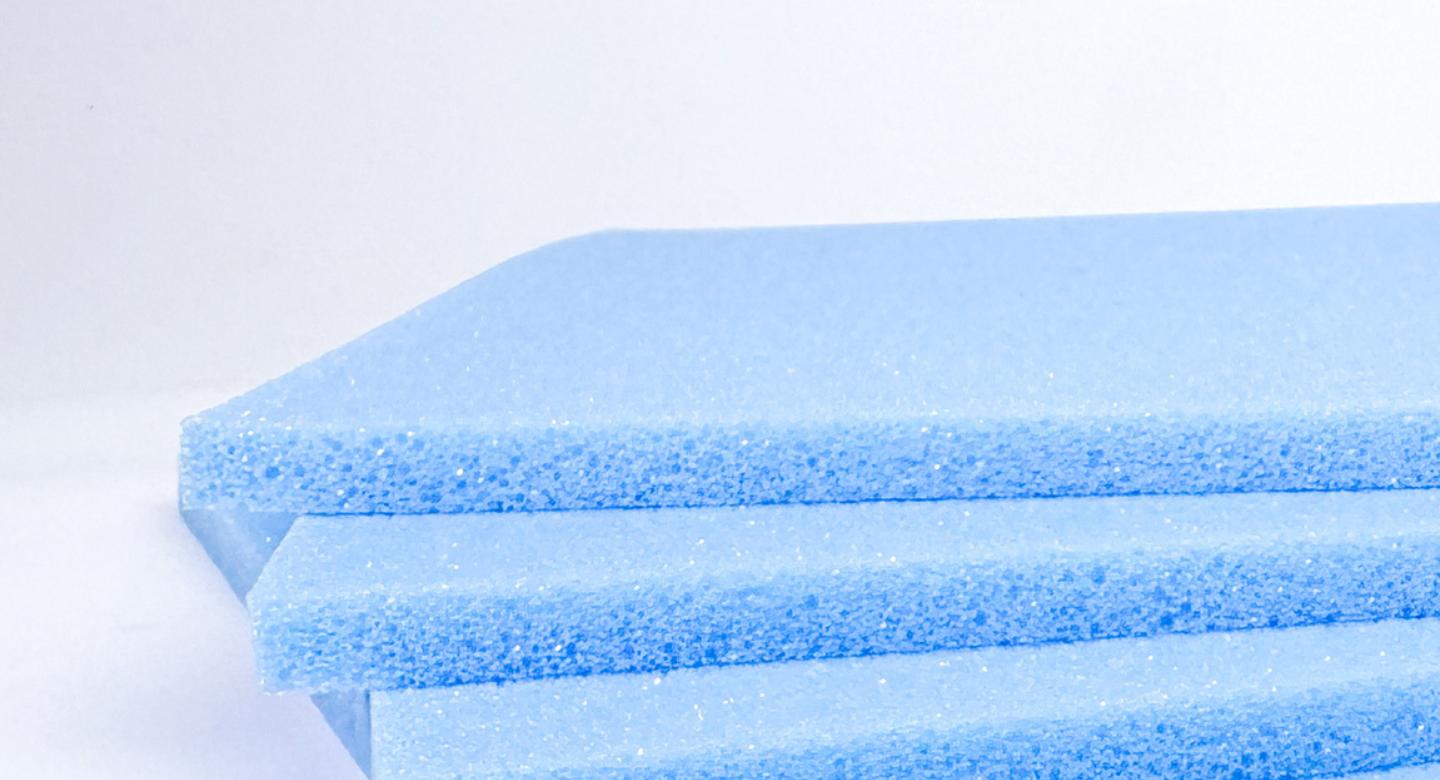

FilterFoam blocks made from shredded scraps of various foam types, ideal for heavy-duty use. This is our most economical line.

Filter

Not sure which product to choose?

Contact us to speak with an advisor.

Polyurethane foam is widely used in the furniture and mattress industry due to its properties of comfort, support, and durability. It is found in seat and backrest padding for sofas and chairs, in armrests and headrests, in upholstered furniture filling, in wall panels and headboards, and in the production of mattresses and cushions, either as filling or as a fundamental component (such as the use of memory foam).